Six Head Filling & Capping Machine Manufacturer

Home Six Head Filling & Capping Machine Manufacturer

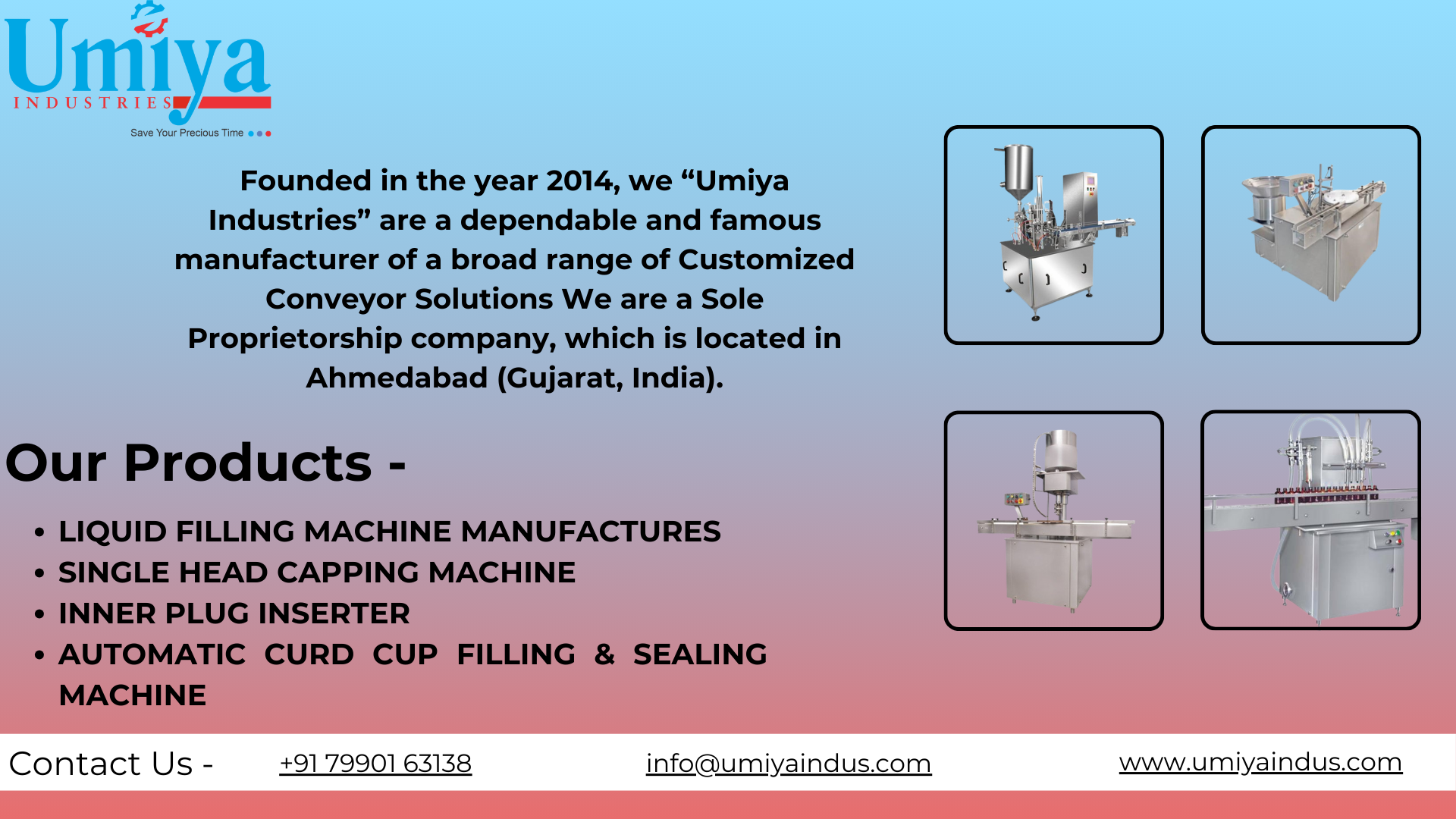

Six Head Filling & Capping Machine Manufacturer

Six Head

Filling & Capping Machine Manufacturer

The Six Head Filling & Capping Machine is an

advanced automated system designed to efficiently fill and cap containers in

various industries. Equipped with six filling heads, it ensures high-speed

operations, precise filling volumes, and consistent capping, making it ideal

for medium to large-scale production lines. This machine enhances productivity,

reduces manual labor, and maintains high hygiene standards, meeting the

stringent requirements of industries such as pharmaceuticals, cosmetics, food

and beverages, and chemicals.

Frequently

Asked Questions (FAQs)

- What

types of containers can the Six Head Filling & Capping Machine handle?

- Is

the machine suitable for both liquid and viscous products?

- Yes,

the machine is designed to handle both liquid and viscous products, such

as oils, creams, and syrups.

- What

is the typical filling speed of the machine?

- Depending

on the model and product characteristics, the machine can achieve speeds

ranging from 30 to 80 bottles per minute.

- Can

the filling volume be adjusted?

- Yes,

the filling volume is adjustable and can be set via the machine's control

panel to meet specific production requirements.

- Is

the machine easy to clean and maintain?

- Absolutely.

The machine is designed with hygiene in mind, featuring easy-to-clean

surfaces and components, and requires minimal maintenance.

- Does

the machine support different cap types?

- Yes,

it supports various cap types, including screw caps, ROPP caps, and pump

heads, depending on the specific model.

- Is

the machine compliant with industry standards?

- Yes,

the machine is designed to comply with GMP (Good Manufacturing Practices)

and other relevant industry standards.

- What

materials are used in the construction of the machine?

- The

machine is constructed using high-quality stainless steel (SS 304/316) to

ensure durability and resistance to corrosion.

- Can

the machine be integrated with other packaging equipment?

- Yes,

it can be integrated with labelling machines, conveyors, and other

packaging equipment to form a complete production line.

- What

is the power requirement for the machine?

- The

power requirement varies by model but typically ranges from 2 kW to 3 HP,

operating on a 3-phase electrical supply.

Applications

- Pharmaceuticals:

Filling and capping of medicines, syrups, and other liquid pharmaceutical products.

- Cosmetics:

Packaging of lotions, creams, shampoos, and other cosmetic liquids.

- Food

& Beverages: Filling of sauces, juices, oils, and other consumable

liquids.

- Chemicals:

Packaging of cleaning agents, solvents, and other chemical products.

- Agriculture:

Filling of pesticides and fertilizers.

Features

with Uses

- Six

Filling Heads: Allows for simultaneous filling of multiple containers, increasing production efficiency.

- Adjustable

Filling Volume: Enables precise control over the amount of product

dispensed.

- No

Bottle - No Fill System: Prevents wastage by ensuring filling only

occurs when a bottle is present.

- Anti-Drip

Nozzles: Minimizes product wastage and maintains cleanliness.

- PLC

Control System: Facilitates easy operation and monitoring of the

filling and capping process.

- Stainless

Steel Construction: Ensures durability and compliance with hygiene

standards.

Benefits

- Increased

Productivity: High-speed operations lead to greater output.

- Reduced

Labor Costs: Automation decreases the need for manual labor.

- Consistent

Quality: Precise filling and capping ensure uniform product quality.

- Compliance

with Standards: Meets industry standards, ensuring product safety and

quality.

- Ease

of Maintenance: User-friendly design simplifies cleaning and

maintenance tasks.

Key

Points

- Suitable for a wide range of industries.

- Enhances

production efficiency and product consistency.

- Complies

with GMP and other industry standards.

- Features

user-friendly controls and easy maintenance.

- Offers

flexibility to handle various container sizes and cap types.

Conclusion

The Six Head Filling & Capping Machine is a versatile

and efficient solution for industries requiring high-speed and precise filling

and capping operations. Its advanced features, such as adjustable filling

volumes, anti-drip nozzles, and PLC control, make it an invaluable asset for

modern production lines. By investing in this machine, companies can achieve

higher productivity, consistent product quality, and compliance with industry

standards, ultimately leading to reduced operational costs and increased profitability.

Contact

Us For More Details On :

Call -

+91 79901 63138

Facebook - www.facebook.com/profile.php?id=100067626623882

Instagram - www.instagram.com/umiyaindustries2015

Youtube - www.youtube.com/@UmiyaIndustries-mn8fm

Website - www.umiyaindus.com

Email -

umiyaindustries16102012@gmail.com | info@umiyaindus.com

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.