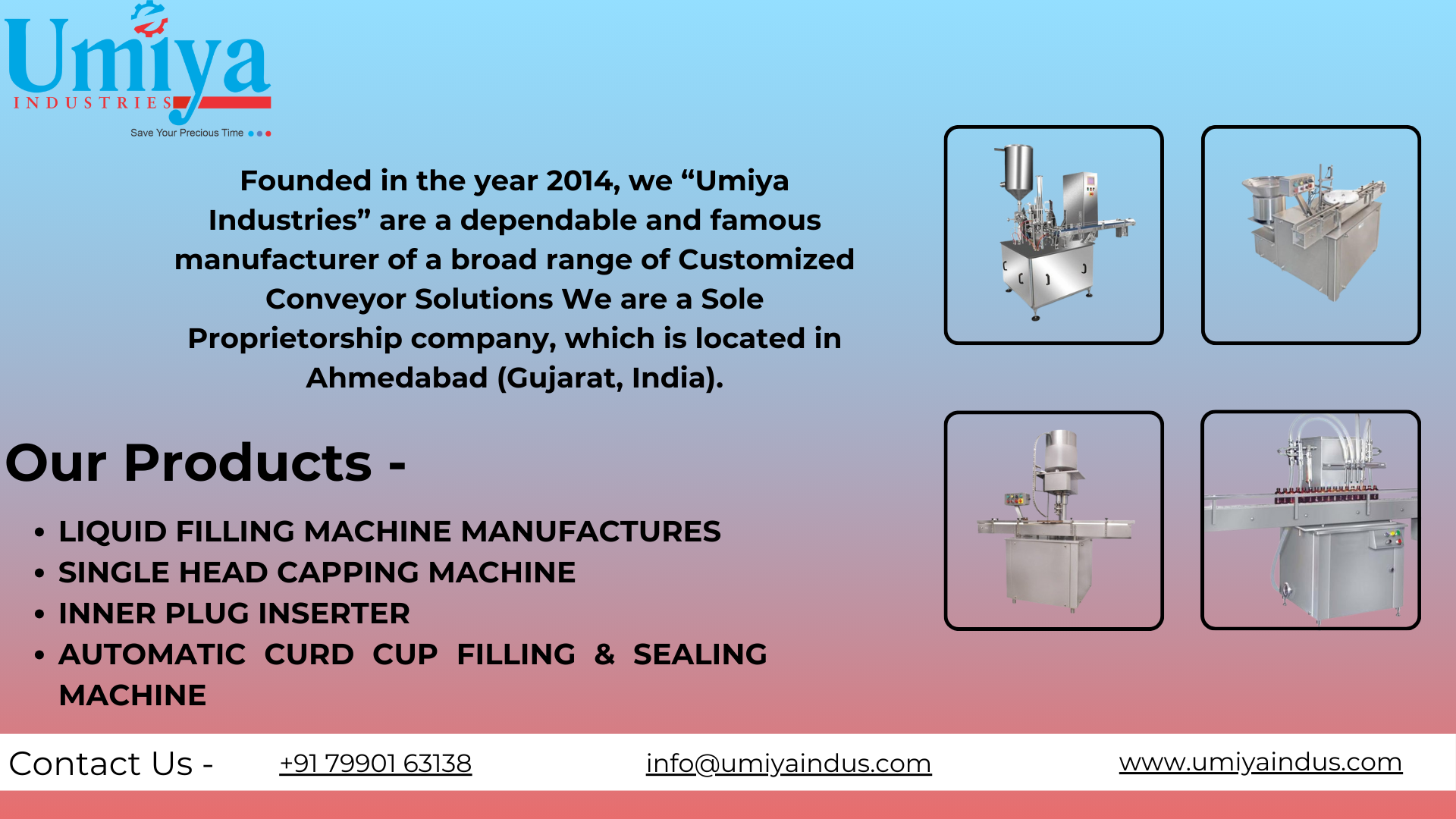

Two Head Filling & Capping Machine

Two Head Filling & Capping Machine

A Two Head Filling & Capping Machine is a compact, semi-automatic or fully automatic machine used in industries to fill liquids or semi-liquids into bottles or containers and then seal them with caps. It is ideal for small to medium production lines requiring speed, precision, and versatility.

Where It’s Used (Applications)

Industry |

Application Example |

|---|---|

| Pharmaceuticals | Syrups, tonics, eye/ear drops |

| FMCG (Cosmetics) | Shampoos, lotions, hand wash |

| Food & Beverages | Juices, sauces, edible oil, honey |

| Chemical Industry | Detergents, toilet cleaners, agrochemicals |

| Ayurveda & Herbal | Herbal oils, tinctures, herbal syrups |

| Lube/Oil Industry | Engine oils, gear oils, brake fluids |

Uses and Operation

-

Filling: Liquid is filled into containers through 2 filling nozzles simultaneously using volumetric or piston-based systems.

-

Capping: After filling, the bottles automatically move to the capping head where caps are placed and tightened.

This integrated mechanism helps in speeding up production, reducing manual labor, and improving hygiene.

Key Features

-

Dual Head Filling for higher throughput

-

Adjustable Fill Volume for different container sizes

-

Contact Parts in SS316/304 (GMP compliant)

-

Touchscreen HMI / PLC Control (Optional)

-

Production Capacity: 20–50 bottles/min depending on volume

Importance & Significance

-

Improves production speed in SMEs and growing industries

-

Reduces manual contamination and labor dependency

Ideal for startups and mid-sized manufacturers

-

Low maintenance, high return on investment (ROI)

(Leading Brands)

-

Multipack Machinery – Ahmedabad

-

Adinath International – Ahmedabad

Harsiddh Engineering Co. – Ahmedabad

Brothers Pharmamach – Gujarat

-

Siddhivinayak Automation – Mumbai

-

Dynamic Enterprises – Mumbai

-

Vibgyor Pharma Machinery – Thane

-

Shree Bhagwati Machtech – Ahmedabad

FAQs

Question |

Answer |

|---|---|

| 1. What liquids can it fill? | Water, oil, syrups, chemicals, shampoo, etc. |

| 2. Is it suitable for all bottle sizes? | Yes, with change parts and adjustments. |

| 3. What is the filling accuracy? | ±1% typically, higher with servo systems. |

| 4. What is the output per minute? | 20–50 bottles/min depending on viscosity and volume. |

| 5. Can it cap different types? | Yes – ROPP, screw caps, flip-top, CRC, etc. |

| 6. What power supply is needed? | Typically single-phase or 3-phase AC, 220–440V. |

| 7. Is it GMP compliant? | Yes, for pharma-grade models. |

| 8. Is training provided? | Most suppliers provide basic training and manuals. |

| 9. Is it upgradeable to 4-head or more? | Yes, modular upgrades possible. |

| 10. What is the delivery time? | 3–6 weeks for standard machines. |

Why Choose Indian Suppliers?

Globally Competitive Prices

ISO/GMP Compliant Machinery

Strong After-Sales & Spares Support

Customized & Export-Quality Build

Widely Exported to Africa, UAE, Southeast Asia, USA

Quick Delivery & Local Support in India

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.