Cap Sealing Machine Manufacturers

Cap Sealing Machine Manufacturers

Applications

Cap sealing machines are utilized in numerous sectors:

-

Pharmaceuticals: Sealing vials and bottles to maintain sterility and prevent contamination.

-

Food & Beverages: Ensuring airtight seals on jars and bottles to preserve freshness.

-

Cosmetics: Securing containers of creams, lotions, and other personal care products.

-

Chemicals: Preventing leaks and ensuring safe storage of chemical substances.

-

Agriculture: Sealing containers of fertilizers, pesticides, and other agrochemicals.

Key Features

-

Versatility: Compatible with various cap types, including screw caps, ROPP caps, lug caps, and snap-fit caps.

-

Automation Levels: Available in manual, semi-automatic, and fully automatic models to suit different production scales.

-

Precision: Ensures consistent torque application for uniform sealing.

-

Hygienic Design: Constructed with materials that meet sanitary standards, crucial for food and pharmaceutical applications.

-

User-Friendly Interface: Equipped with intuitive controls for easy operation and adjustments.(adinathmachines.com, bhagwatilabeling.com)

Benefits

-

Product Integrity: Provides tamper-evident seals, assuring consumers of product safety.

-

Extended Shelf Life: Airtight seals prevent contamination and spoilage.

-

Operational Efficiency: Automated machines increase production speed and reduce manual labor.

-

Cost-Effective: Minimizes product wastage due to leaks or contamination.

-

Compliance: Meets industry regulations for packaging and safety standards.(zimapack.com)

Types of Cap Sealing Machines

-

ROPP (Roll-On Pilfer Proof) Capping Machines: Ideal for sealing aluminum caps on bottles, commonly used in the beverage and pharmaceutical industries.

-

Screw Capping Machines: Suitable for plastic and metal screw caps, widely used across various sectors.

-

Lug Capping Machines: Designed for twist-off caps, often used in food packaging.

-

Snap Fit Capping Machines: For caps that snap onto containers without threading.

-

Induction Cap Sealing Machines: Utilize electromagnetic induction to seal foil liners inside caps, providing a hermetic and tamper-evident seal.(senieer.com, zimapack.com, enerconind.com)

Leading Cap Sealing Machine Manufacturers in India

-

Lodha International LLP: Offers advanced cap sealing machines suitable for bottles and vials of various shapes and sizes.

-

N.K. Industries: Provides a wide range of capping machines, including automatic vial cap sealing machines and screw capping machines.

-

Adinath International: Manufactures cap sealing machines known for their durability and performance across multiple industries.

-

Gtech Packaging India Pvt. Ltd.: Specializes in automatic cap sealing machines with high efficiency.

-

Dynamic Enterprises: Offers induction cap sealing machines suitable for various industrial applications.

-

Monarch Appliances Pvt. Ltd.: Provides foil sealing machines and cap sealers for diverse packaging needs.

-

Maharani Machine & Textiles: Manufactures a range of cap sealing machines, including options for tin and bottle sealing. (lodhapharma.com, nkpharmamachinery.com, gtechpackaging.com, bhagwatilabeling.com, monarchpackaging.com)

Frequently Asked Questions (FAQs)

-

What is the primary function of a cap sealing machine?

-

To securely seal caps onto containers, ensuring product safety and integrity.(zimapack.com)

-

-

Can cap sealing machines handle different cap sizes?

-

Yes, most machines are adjustable or come with interchangeable parts to accommodate various cap sizes.

-

-

Are these machines suitable for all container materials?

-

Generally, yes. However, it's essential to select a machine compatible with the specific materials used.

-

-

What maintenance is required for cap sealing machines?

-

Regular cleaning, lubrication, and inspection of parts to ensure optimal performance.

-

-

Can these machines be integrated into existing production lines?

-

Yes, many cap sealing machines are designed for seamless integration into automated production lines.

-

-

Do cap sealing machines provide tamper-evident seals?

-

Yes, especially induction sealing machines, which offer tamper-evident and hermetic seals.(lepel.com)

-

-

What is the difference between manual and automatic cap sealing machines?

-

Manual machines require human intervention for each operation, while automatic machines function with minimal human input, offering higher efficiency.

-

-

Are there machines suitable for small-scale operations?

-

Yes, semi-automatic and manual cap sealing machines are ideal for small-scale or startup operations.(maharanimachine.com)

-

-

How do I choose the right cap sealing machine for my needs?

-

Consider factors like production volume, container and cap types, and level of automation required.

-

-

Is training required to operate these machines?

-

Basic training is recommended to ensure safe and efficient operation.

-

Significance in Modern Industries

Cap sealing machines play a vital role in ensuring product quality, safety, and compliance with industry standards. By providing secure seals, they protect products from contamination, extend shelf life, and enhance consumer trust. Their integration into production lines streamlines operations, reduces manual labor, and increases overall efficiency.

Filter Using Product Tags

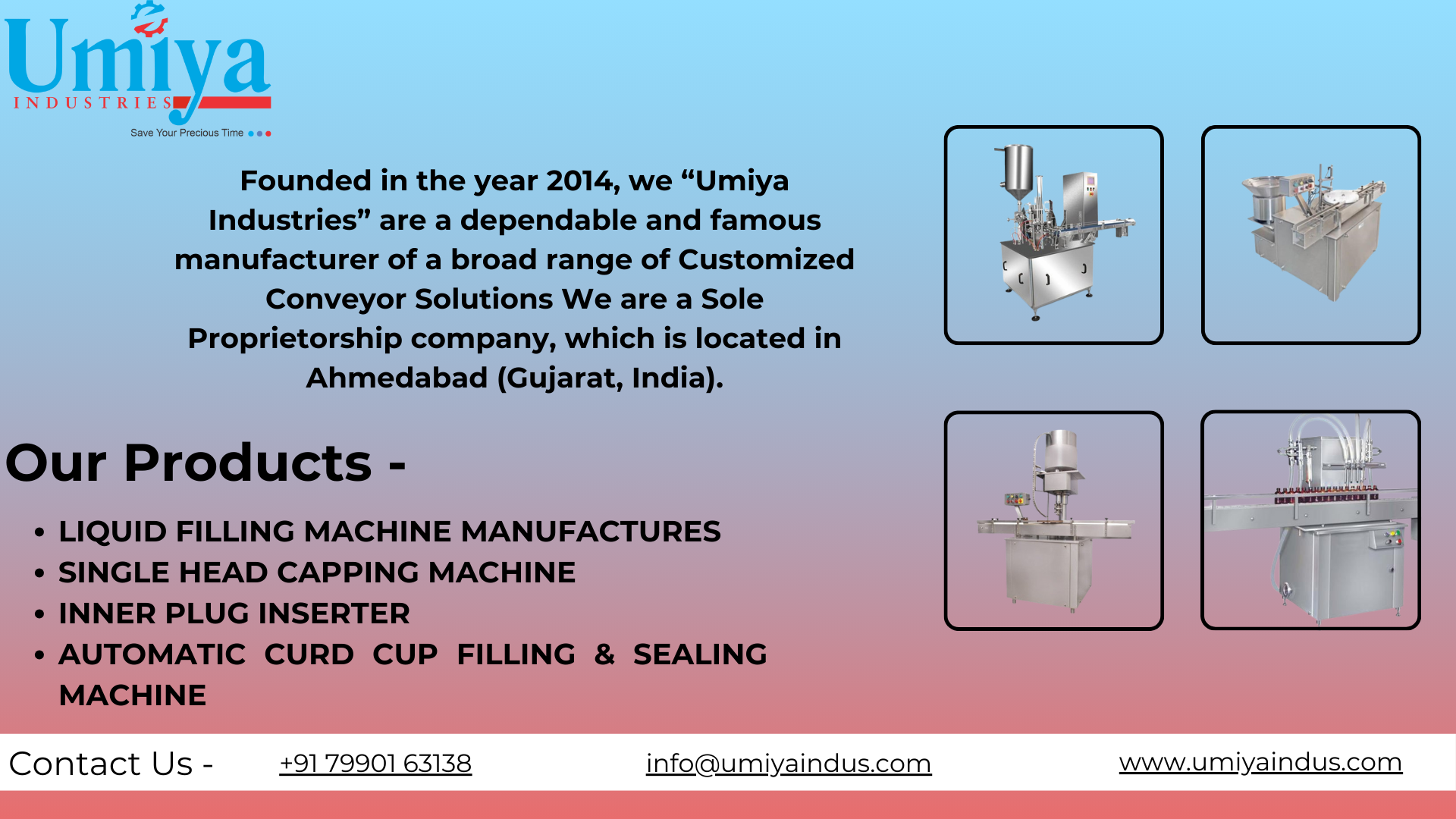

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.