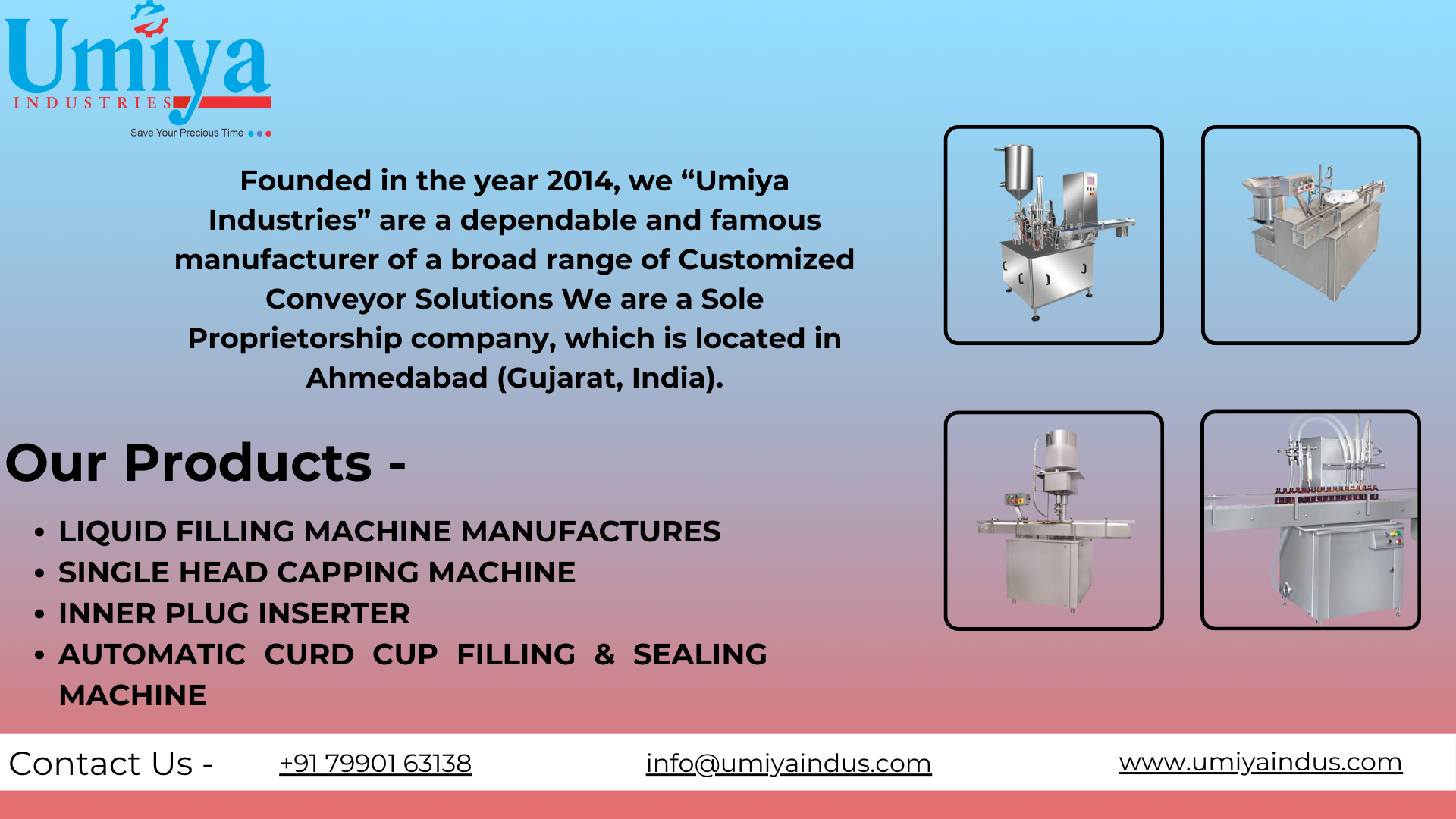

Manual Monoblock Filling and Capping Machine

Manual

Monoblock Filling and Capping Machine

A Manual Monoblock Filling and Capping Machine is a

compact, user-friendly system designed for the small-scale or startup packaging

industry. This equipment integrates both liquid filling and capping

processes into a single unit, improving operational efficiency and reducing

manpower requirements. It is ideal for low to moderate production volumes,

offering precise filling and reliable capping for bottles, jars, or vials.

These machines are widely used in pharmaceuticals, food

& beverages, cosmetics, agrochemicals, and more, where flexibility,

accuracy, and hygiene are critical.

Features

with Uses

|

Feature |

Use |

|

Dual Operation (Filling + Capping) |

Saves space and streamlines packaging by combining two essential tasks. |

Manual Operation |

Ideal for startups and small batches; reduces investment

in automation. |

|

Adjustable Nozzle & Volume Control |

Ensures accurate filling volumes and minimizes wastage. |

|

Stainless Steel Body (SS 304/316) |

Corrosion-resistant and compliant with hygiene standards. |

|

Interchangeable Bottle Holders |

Accommodates various bottle shapes and sizes. |

|

Compact Design |

Suitable for limited space environments or mobile setups. |

|

Leak-Proof Capping Mechanism |

Ensures tight and secure sealing to prevent contamination. |

|

Easy to Clean and Maintain |

Quick dismantling and reassembly for cleaning. |

|

No Electricity Required (Optional) |

Some models run completely manually for use in

power-restricted areas. |

|

Portable Structure |

Easy to shift and install in multiple locations. |

Applications

- Pharmaceuticals

– Syrup, liquid medicines, tonics.

- Cosmetics

– Shampoos, lotions, oils.

- Food

& Beverages – Juices, sauces, vinegar, water bottles.

- Agrochemical

– Fertilizer solutions, pesticides.

- Chemical

Industry – Cleaners, solvents, oils.

- Essential

Oils & Herbal Products – Aromatherapy oils, herbal extracts.

- Startups

and R&D Labs – Ideal for prototype packaging or batch testing.

Key

Points

- Integrated filling and capping unit.

- Best

suited for small to medium production capacity (200–1000 bottles/hour).

- Manual

operation reduces power dependency.

- High

return on investment for low-scale packaging units.

- Available

in semi-automatic upgrade options.

Top 10

FAQs about Manual Monoblock Filling and Capping Machine

1. What is a manual monoblock filling and capping

machine?

2. What type of bottles can it handle?

It can handle plastic, glass, PET, and HDPE bottles

depending on the model and custom fittings.

3. Is it suitable for food-grade applications?

Yes, models built with SS 304/316 material are suitable for

hygienic food and pharmaceutical applications.

4. What is the typical production speed?

It can fill and cap around 200 to 1000 bottles per hour,

depending on operator efficiency and liquid type.

5. Can the fill volume be adjusted?

Yes, the fill volume is adjustable via the volume control

knob or syringe setting.

6. What kind of caps does it support?

It supports screw caps, flip-tops, press-fit caps, and ROPP

caps based on custom setups.

7. Is training required to operate the machine?

Basic training is usually sufficient; the machine is simple

to operate.

8. Can it fill thick or viscous liquids?

Yes, with appropriate nozzles and pump types (likepiston-based), it can handle viscous products.

9. Is it upgradeable to semi-automatic or automatic

versions?

Yes, many manufacturers offer upgrade options for automation

when production demand increases.

10. What is the maintenance requirement?

Minimal – mostly limited to cleaning and periodic

lubrication of moving parts.

Contact

Us For More Details On :

Call - +91

79901 63138

Facebook - www.facebook.com/profile.php?id=100067626623882

Instagram - www.instagram.com/umiyaindustries2015

Youtube - www.youtube.com/@UmiyaIndustries-mn8fm

Website - www.umiyaindus.com

Email - umiyaindustries16102012@gmail.com |

info@umiyaindus.com

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.