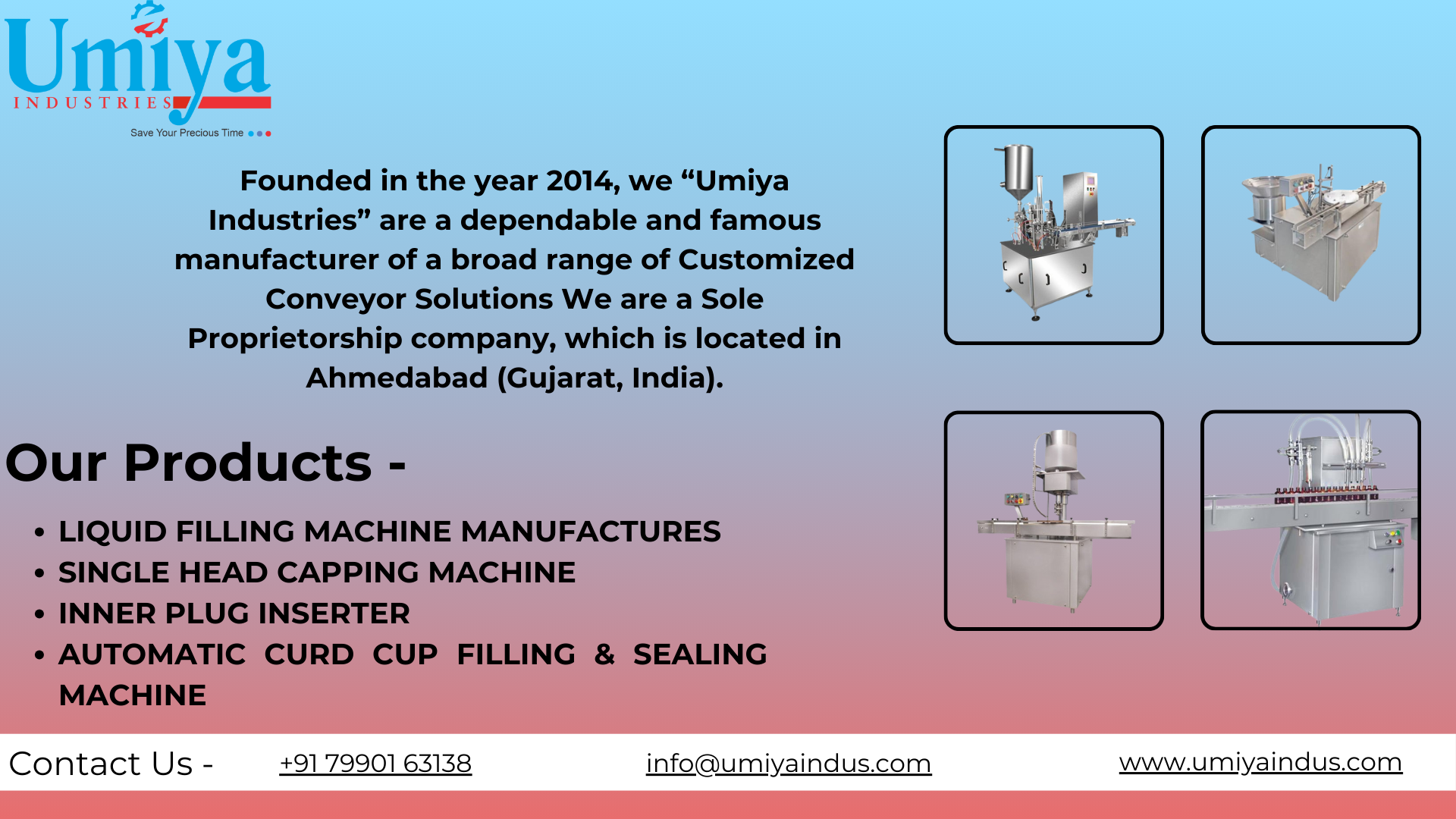

Automatic Monoblock Filling and Capping Machine

Home Automatic Monoblock Filling and Capping Machine

Automatic Monoblock Filling and Capping Machine

Automatic

Monoblock Filling and Capping Machine

An Automatic Monoblock Filling and Capping Machine is

an advanced, fully integrated system that combines automated liquid filling

and container capping into a single streamlined unit. Designed for high-speed

and high-volume production, this machine is widely used in industries like pharmaceuticals,

food & beverages, cosmetics, agrochemicals, and chemicals.

With PLC-controlled operations, servo-driven

filling systems, and precision cap placement, the monoblock design

minimizes operator handling, ensures hygiene, and maximizes productivity with

unmatched accuracy and consistency.

Features

with Uses

|

Feature |

Use |

|

Monoblock Design (Filling + Capping) |

Combines two operations in one frame, saving space and time. |

PLC & HMI Touchscreen Interface |

Enables intelligent control and monitoring of all

parameters. |

|

Servo-Driven or Pneumatic Filling Mechanism |

Ensures precise, repeatable filling volumes with minimal

waste. |

|

Automatic Cap Feeder & Cap Placement |

Increases speed and reduces human error in capping. |

|

No Bottle–No Fill–No Cap Sensor System |

Prevents spills and ensures efficient material usage. |

|

SS 304/316 Contact Parts |

Hygienic, corrosion-resistant, and suitable for food and

pharma-grade operations. |

|

Variable Speed Drive (VFD) |

Allows production speed adjustment based on need. |

|

Tool-less Changeover System |

Easy adaptation for different container sizes and formats. |

|

CE & GMP Compliance |

Ensures safety and international quality standards. |

|

Integrated Conveyor System |

Seamless flow of bottles for continuous operation. |

Key

Points

- Ideal for medium to large-scale production lines.

- Handles

30 to 200+ bottles per minute depending on configuration.

- Suitable

for round, square, flat bottles made of PET, HDPE, or glass.

- Ensures

leak-proof capping and accurate filling within ±0.5% variation.

- Customizable

nozzle types: gravity, piston, peristaltic, or gear pump.

- Reduces

human intervention, thereby minimizing contamination risks.

- Compatible

with cleanroom environments and laminar flow systems.

Applications

- Pharmaceutical

Industry – Syrups, oral liquids, suspensions, tonics.

- Food

& Beverage Industry – Juices, energy drinks, sauces, edible oils.

- Cosmetics

& Personal Care – Lotions, shampoos, creams, gels.

- Chemical

Industry – Detergents, solvents, lubricants.

- Agrochemical

Sector – Pesticides, herbicides, liquid fertilizers.

- Dairy

& Nutraceuticals – Flavored milk, dietary supplements, protein

drinks.

Top 10

FAQs (Frequently Asked Questions)

1. What is an Automatic Monoblock Filling and Capping

Machine?

2. What is the production speed of this machine?

Depending on the model, it can handle 30 to 200+ bottles per

minute.

3. Can it fill both thick and thin liquids?

Yes. With the right filling system (piston, gear,

peristaltic), it can handle low to high viscosity liquids.

4. Is it compatible with different bottle shapes and

sizes?

Yes. Most machines allow quick changeover kits for various

containers – round, flat, square, etc.

5. How accurate is the filling operation?

Typically maintains ±0.5% filling accuracy, depending on the filling mechanism.

6. Does it require skilled operators?

Basic training is enough. The HMI interface makes it

user-friendly and easy to manage

7. Can the machine be integrated with other packaging

lines?

Yes. It can be connected with labeling, induction sealing,

and shrink-wrapping machines for a complete packaging solution.

8. What type of caps does it support?

Supports screw caps, ROPP caps, flip-tops, CRC, pump caps,

etc.

9. What materials are used for construction?

Mainly stainless steel (SS 304 or SS 316 for pharma-grade).

Optional acrylic or polycarbonate safety enclosures are also available.

10. What maintenance is required?

Routine lubrication, cleaning, filter checks, and sensor

calibration. Preventive maintenance ensures long machine life.

Contact

Us For More Details On :

Call -

+91 79901 63138

Facebook - www.facebook.com/profile.php?id=100067626623882

Instagram - www.instagram.com/umiyaindustries2015

Youtube - www.youtube.com/@UmiyaIndustries-mn8fm

Website - www.umiyaindus.com

Email -

umiyaindustries16102012@gmail.com | info@umiyaindus.com

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.