Mono Block Volumetric Liquid Filling Machine

Mono

Block Volumetric Liquid Filling Machine

Product

Description:

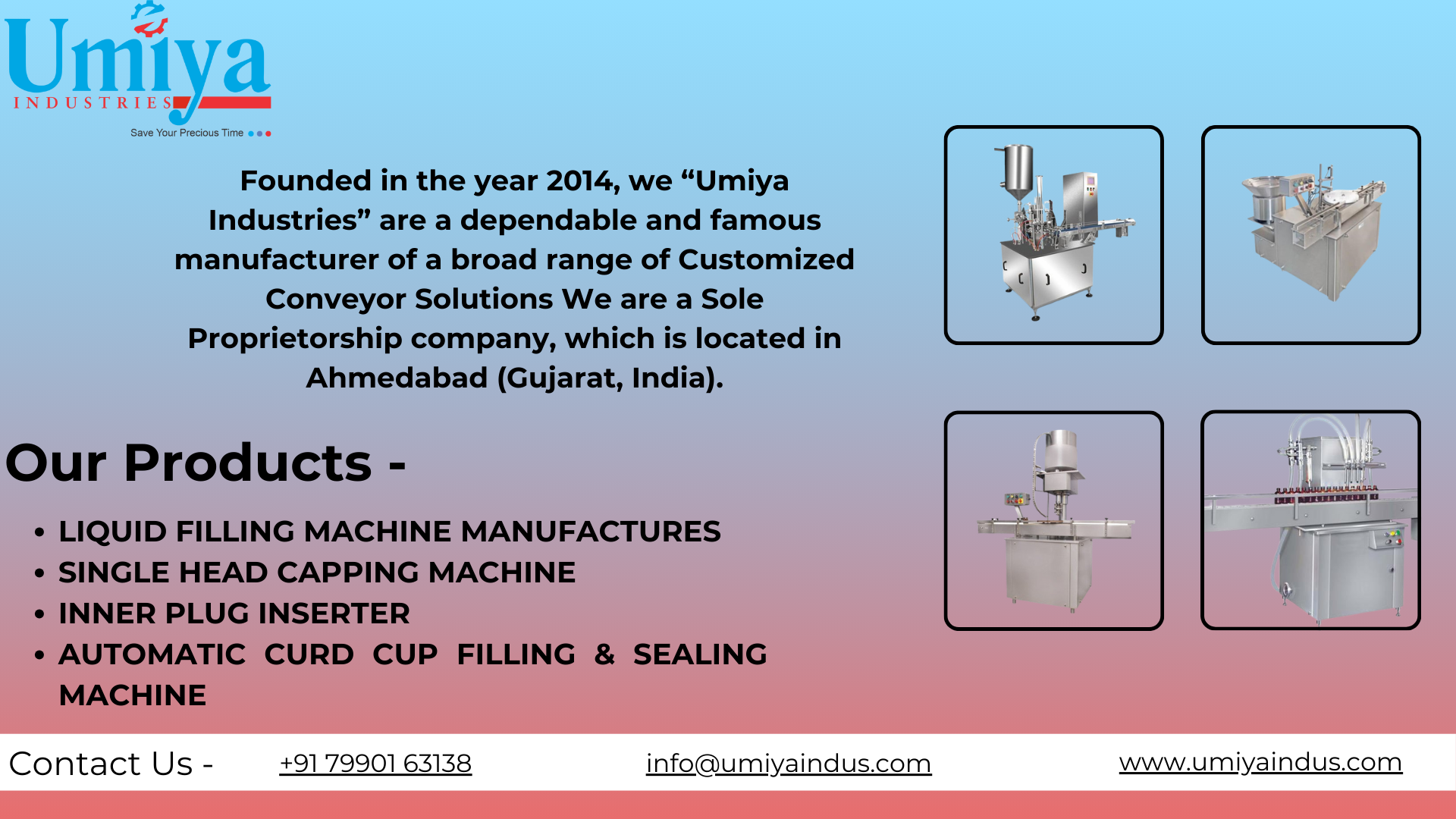

A Mono Block Volumetric Liquid Filling Machine is a

highly efficient, integrated solution designed for precise filling and sealing

of various liquid products in containers. This machine combines both filling

and capping stations on a single base frame (mono block), ensuring smooth

and synchronized operations with minimal space requirement. Built for speed,

accuracy, and hygiene, it’s ideal for industries where consistent fill volumes

and secure packaging are critical.

Using volumetric principles, the machine measures and

dispenses accurate volumes of liquid through pistons or flow meters, making it

ideal for free-flowing liquids such as syrups, juices, lotions, oils, and

pharmaceutical solutions.

Key

Features & Their Uses:

|

Feature |

Use/Benefit |

|

Volumetric Filling Technology |

Ensures accurate and consistent fill volume, minimizing product wastage. |

Mono Block Design |

Combines filling and capping in one compact unit, saving

floor space and reducing handling. |

|

Servo/Mechanical Driven Pistons |

Enhances accuracy and flexibility in filling volume

adjustment. |

|

No-Container-No-Fill System |

Prevents spillage and product loss when containers are

missing. |

|

Stainless Steel Contact Parts (SS316/SS304) |

Ensures hygiene and corrosion resistance, ideal for pharma

and food-grade products. |

|

Adjustable Speed Control (VFD/PLC) |

Allows synchronization with conveyor speed and production

line. |

|

CIP/SIP Compatibility |

Enables in-place cleaning and sterilization for

pharmaceutical operations. |

|

Tool-less Changeover |

Quick format change for different bottle sizes without

needing specialized tools. |

|

Drip-Free Nozzles |

Prevents dripping or spillage, ensuring clean container

filling. |

|

Digital HMI with PLC |

Simplifies operation, monitoring, and customization of

parameters. |

Applications:

The Mono Block Volumetric Liquid Filling Machine is used in

industries such as:

- Pharmaceuticals:

Syrups, antiseptics, oral solutions.

- Food

& Beverage: Juices, milk, sauces, flavored waters.

- Cosmetics

& Personal Care: Lotions, shampoo, hand wash, oils.

- Chemical

& Agro: Disinfectants, pesticides, solvents.

- Dairy

Industry: Liquid dairy products in bottles.

- Ayurvedic

and Herbal Products: Tonics, oils, herbal extracts.

10 Most

Common FAQs:

1. What is a mono block liquid filling machine?

2. How does the volumetric filling system work?

It fills liquid based on set volume using pistons or flow

meters for accurate dosing.

3. Can it handle different bottle sizes?

Yes, most models offer quick changeover features for various

bottle sizes and shapes.

4. Is it suitable for viscous liquids?

Yes, depending on the pump configuration and nozzle design,

it can handle low to medium-viscosity liquids.

5. What is the filling accuracy?

Typical filling accuracy is ±1% or better, depending on the

liquid type and volume.

6. Can I clean the machine without disassembling it?

Yes, CIP/SIP systems are often integrated for automatic

cleaning without dismantling.

7. What type of bottles can it fill?

Glass, PET, HDPE, and other plastic containers commonly used

in various industries.

8. How many heads can the machine have?

Usually ranges from 2 to 12 heads depending on production

requirements.

9. Is it customizable for specific industry needs?

Yes, machines can be tailored with specific features like

flame-proof design, HEPA filters, or laminar flow for pharma-grade operations.

10. What are the power requirements?

Generally 3-phase with options from 1-3 kW depending on the

machine size and automation level.

Key

Points Summary:

- Machine

Type: Mono Block, Automatic

- Technology:

Volumetric (Piston/Flow Meter)

- Material

Compatibility: Non-viscous to semi-viscous liquids

- Industries:

Pharma, Food, Cosmetics, Chemical

- Bottle

Types: Glass, PET, HDPE

- Operation:

PLC-controlled with HMI

- Cleanability:

CIP/SIP Optional

- Fill

Range: Typically from 30 ml to 1000 ml (customizable)

- Output:

Up to 100 bottles/min (depends on heads and volume)

Contact

Us For More Details On :

Call - +91

79901 63138

Facebook - www.facebook.com/profile.php?id=100067626623882

Instagram - www.instagram.com/umiyaindustries2015

Youtube - www.youtube.com/@UmiyaIndustries-mn8fm

Website - www.umiyaindus.com

Email - umiyaindustries16102012@gmail.com |

info@umiyaindus.co

Filter Using Product Tags

Our Products

Get In Touch

Shed No 31, Global Business Park, Opp. Madhav Evanue , Near Jahnavi Arcade, S.P. Ring Road, Odhav, Ahmedabad.

umiyaindustries16102012@gmail.com

info@umiyaindus.com

+91 79901 63138

© Umity Industries. All Rights Reserved.